Advantages of Computer Integrated Manufacturing

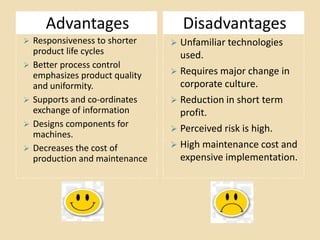

Advantages and disadvantages of CIM in relation to initial investment and maintenance. Computer automated manufacturing is assisting in the reduction.

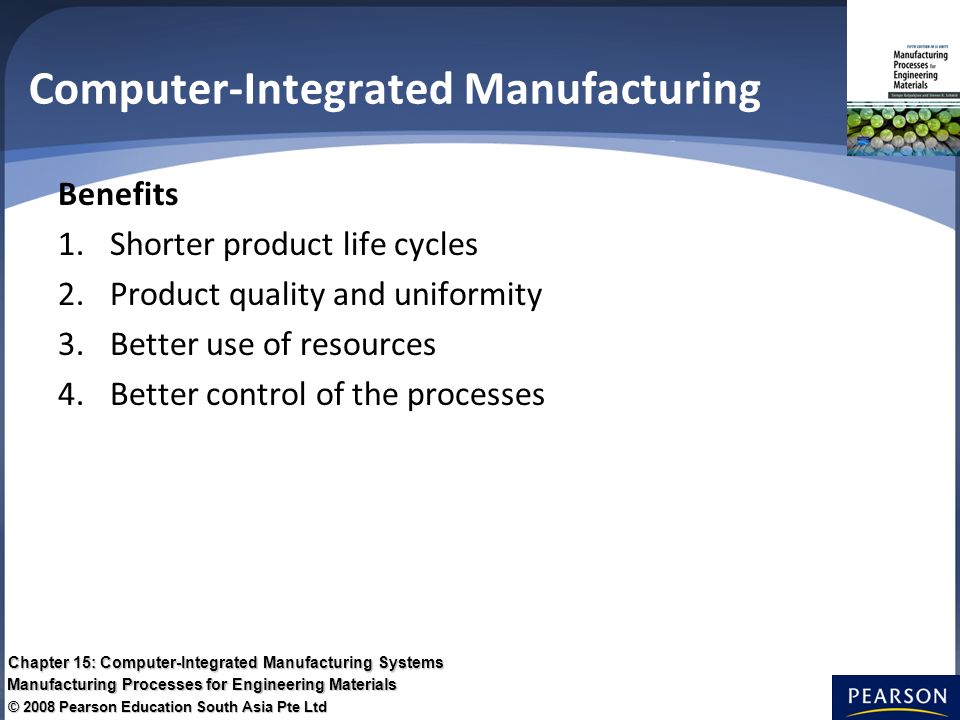

Chapter 15 Computer Integrated Manufacturing Systems Ppt Video Online Download

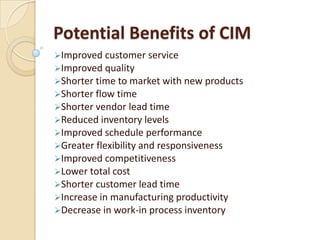

Quality and manufacturing flexibility reduction of cost lead time as well as enhanced manufacturing processes.

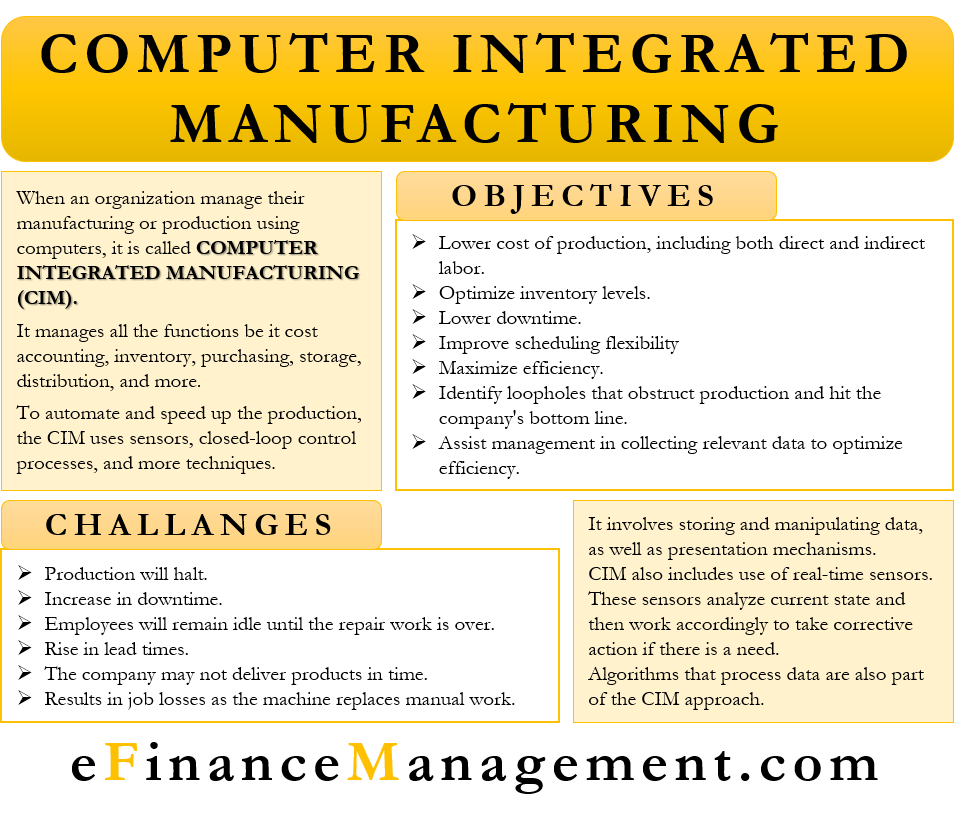

. This integration allows individual processes to exchange. Computer-integrated manufacturing is the manufacturing approach of using computers to control entire production process. Despite the potential of computer-integrated manufacturing CIM to improve quality and productivity while reducing costs successful implementations are more the exception.

Bring together siloed information streams for business-wide improvements. The sole objective of computer-integrated manufacturing is to streamline production. Smart manufacturing refers to an advanced mode of manufacturing which incorporates computer-integrated manufacturing CIM and artificial intelligence AI for data-enabled.

CIM reduces errors in the manufacturing process. Reduces the delivery time. Manufacturing Method As a method of manufacturing three components distinguish CIM from other manufacturing methodologies.

The type and location. Benefits of computer integrated manufacturing Time-efficiency. The benefits of computer integrated manufacturing include not only optimizing the production and business processes but also providing data storage data processing and real time.

Advantages of Computer-Aided Manufacturing. Adoption of a computer integrated. It improves the quality of the product.

What are the advantages of computer-integrated manufacturing in manufacturing industries. Every process from the production line to the storage and distribution is carefully monitored to ensure maximum efficiency throughout the entire manufacturing process. A fully automated system can operate much faster and work 247 if required.

Let us look at the top benefits of computer integrated manufacturing It reduces the overall manufacturing cost. Computer integrated manufacturing has the advantage of possessing intelligence to maximise the process provided process is well understood and all parameters can be measured in real. It improves the quality.

Integration does what the name. The sole objective of computer-integrated manufacturing is to streamline production processes delivering the following benefits. Examples of these functions are planning the step-by-step processes for the product part programming in numerical control and scheduling the production operations in the factory.

Means for data storage retrieval. CIMS EVOLUTION OF COMPUTER INTEGRATED MANUFACTURING Since 70s numerical controllers are being designed around microprocessors resulting in compact CNC. Reduced costs ie.

Computer integrated manufacturing CIM have many advantages over traditional manufacturing methods as we can say. The cost of direct and indirect labour. 5 key benefits of computer-integrated manufacturing 1.

System is constantly monitored so if there is a breakdown. As shown in Figure 1 the major elements of CIM include.

Computer Integrated Manufacturing Cim Meaning Objectives And More

Computer Integrated Manufacturing

No comments for "Advantages of Computer Integrated Manufacturing"

Post a Comment